2 min read

Hot Stamping Dies Explained: Brass, Steel, and Magnesium

Matt Martin

Tue, Jan 21, 2025 @ 08:01 AM

Hot stamping technology stands at the forefront of modern marking solutions, offering industrial buyers a perfect blend of versatility, economy, and professional finish. This article explores the various materials and applications of hot stamping dies, helping you make informed decisions for your specific manufacturing needs.

Understanding Hot Stamping Technology

Hot stamping has revolutionized the marking industry by providing consistent, high-quality impressions across various substrates. The process involves applying heat and pressure through specially designed dies to create permanent, precise marks that maintain their integrity over time.

Material Options for Hot Stamping Dies

Brass Hot Stamping Dies

Brass hot stamping dies have emerged as the preferred choice for many manufacturers, offering several distinct advantages. The material delivers exceptional value through its balance of affordability and durability, making it ideal for businesses that require medium production volumes without compromising on quality.

The material's natural properties allow for precise detail reproduction while maintaining cost-effectiveness over multiple production cycles. It creates remarkably crisp and clean impressions that maintain their quality throughout the production run, ensuring consistent branding and marking across all products.

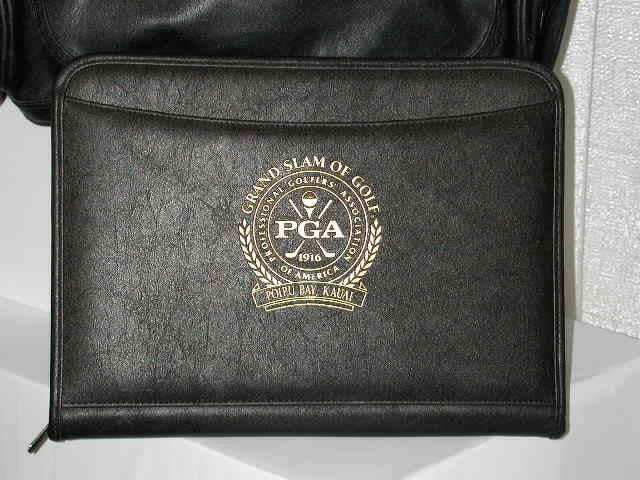

The superior finish quality makes brass dies particularly suitable for applications where visual appeal is paramount. Brass performs excellently across a diverse range of substrates, including books, leather goods, various plastics, paper products, and wooden items, offering versatility that helps maximize return on investment through multiple application possibilities.

Steel Hot Stamping Dies

Steel represents the premium tier in hot stamping technology. Its unmatched durability makes it the optimal choice for high-volume production environments where die longevity is crucial to maintaining operational efficiency.

The robust nature of steel dies ensures they maintain their marking quality even under intensive use conditions. Steel specializes in marking harder materials, notably engineered plastics, and similar robust substrates while maintaining impressive detail retention and mark quality.

This makes steel hot stamping dies invaluable for industrial applications requiring both durability and precision. Furthermore, steel provides exceptional long-term value despite higher initial costs, as their extended lifespan and consistent performance quality significantly reduce the cost per impression over time.

Magnesium Imprinting Dies

Magnesium dies offer unique advantages for specific applications. The material excels in short production runs where flexibility and quick turnaround times are essential, providing cost-effective solutions for smaller batch productions or prototype development phases.

The material's properties allow for rapid die production without compromising mark quality. Magnesium demonstrates remarkable versatility across different imprinting machines, making them an excellent choice for facilities with diverse equipment setups or frequently changing production requirements.

This adaptability extends to various substrates, including plastics, leather, wood, and paper products. The dies offer mounting flexibility with unmounted and mounted options at industry-standard heights, allowing for seamless integration into existing production processes while maintaining consistent marking quality.

Magnesium dies are also ideal for stamping the following items:

- Greeting cards

- Labels

- Book Bindings

- Matchbooks

- Ribbons and bows

- Advertising specialties

- Letterpress

- Jewelry boxes

- Menu covers

- Napkins

Applications Across Industries

Hot stamping technology is used in numerous sectors, from luxury goods manufacturing to industrial marking. The adaptability of different die materials ensures optimal results for specific applications.

For Branding and Marketing, hot stamping enhances product packaging with sophisticated, permanent branding elements, creates distinctive marks on promotional items and corporate gifts, and delivers professional finishes on high-end retail packaging.

For Industrial Applications, the technology provides clear, durable marking solutions for pharmaceutical packaging, enables consistent wire marking and heat shrink sleeving, and creates permanent identification marks on industrial components.

For Consumer Goods, hot stamping produces elegant finishes on cosmetics packaging, creates lasting impressions on leather goods and accessories, and delivers precise marking on paper products and stationery.

Making the Right Choice

When selecting hot stamping dies, several factors come into play. Production volume requirements and expected die lifespan must be carefully considered alongside substrate characteristics and marking requirements. Budget constraints and long-term value considerations should be weighed against specific application needs and quality expectations.

Hot stamping dies have repeatedly proven their worth for pharmaceutical package marking and similar specialized applications requiring consistent, legible results. The technology continues to evolve, offering industrial buyers increasingly sophisticated solutions for their marking needs.

If you want to see how our hot stamping dies helped a long-time customer deliver legible and consistent pharmaceutical package marking, check out our testimonial Hot Stamping Coding Type for Pharmaceutical Packaging. You can also contact us to request a quote.