2 min read

Why You Would Use Metal Type and Type Holder vs. Dot Peen

Matt Martin

Thu, Jan 17, 2019 @ 08:01 AM

Since there's usually more than one way to mark a part, users are often faced with determining which marking method is most appropriate for their application. Part size, material, volume, budget, information to be marked, and other factors influence direct part marking method selection, so it is essential to understand the different methods you have available to you. Here we will consider steel type and type holder setups versus dot peen systems and why you would choose one instead of the other.

Steel Type and Holder

A type and holder setup requires interchangeable steel type, or a logodie, to be paired with a holder (hand held holder in this case). The type is inserted into the holder, the holder is placed on the marking surface, and the end of the holder opposite the type is struck with a hammer to create a permanent mark. Steel type is usually engraved with sharp face Gothic style characters but other faces (low stress, for example) and font styles are available. The depth of mark depends on the material being marked, how many characters, character size, and the weight of the hammer used.

A type and holder setup requires interchangeable steel type, or a logodie, to be paired with a holder (hand held holder in this case). The type is inserted into the holder, the holder is placed on the marking surface, and the end of the holder opposite the type is struck with a hammer to create a permanent mark. Steel type is usually engraved with sharp face Gothic style characters but other faces (low stress, for example) and font styles are available. The depth of mark depends on the material being marked, how many characters, character size, and the weight of the hammer used.

What is Dot Peen Marking?

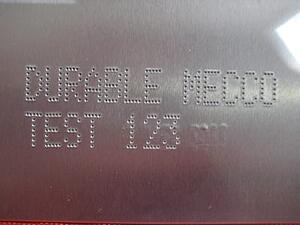

Dot peen marking, or pin stamping, uses a dot peen marking system with carbide styles to create precise, low stress dot patterns onto a substrate. The alphanumeric characters, logos, or 2D data matrix bar codes are programed into the dot peen system and can be marked on a wide range of materials like plastic and metal.

Dot peen marking, or pin stamping, uses a dot peen marking system with carbide styles to create precise, low stress dot patterns onto a substrate. The alphanumeric characters, logos, or 2D data matrix bar codes are programed into the dot peen system and can be marked on a wide range of materials like plastic and metal.

While dot peen marking systems typically provide a low cost of ownership (few consumables), they do require a fairly significant up-front investment.

When Would You Use Steel Type and Holder vs. Dot Peen?

Budget and depth of mark are two reasons why someone might decide to go with steel type and a holder as opposed to a portable dot peen. While a dot peen marking system allows users to program in many types of marks, for many applications this is unnecessary. Applications that require a static part number, for instance, are often better suited to a lower cost steel type and holder set up than a programable dot peen machine.

Depth of mark requirements are also something to consider when choosing your marking method. While dot peen's do offer multiple depth settings, your application may require a deeper mark than can be achieved with a pin stamper (for example, if the part needed to be painted after the mark was made). The use of a holder with steel type and a hammer will typically produce a deeper mark than a portable dot peen.

A type and holder setup is also just easier to use than a dot peen marking system. While a dot peen marking system's software can be simple enough to learn, using a type and holder is certainly less complex.

So, to summarize, applications that require marking static numbers or letters, with above average mark depth, on any size part, and with minimal investment are often best served with a type and holder setup versus dot peen.

Learn More

Click here to see how Durable Technologies can help you make your mark with steel type and holders.